For the first step, a cable is ready for connecting to two sides of connectors. So the purpose of the pretreatment is to clearly expose the wire cores. This step contributes to an efficient cable soldering and signal anti-jamming.

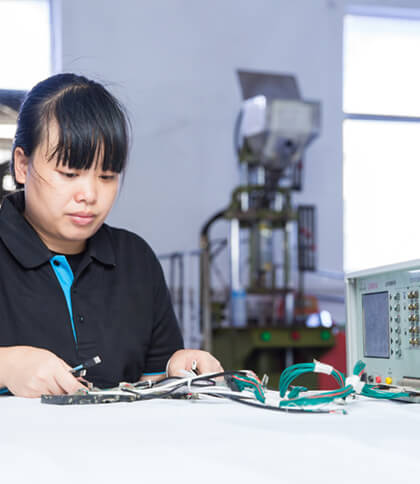

Based on the first step, the precision cable soldering is performed. The skilled craftsmen are strictly picked out and required to be fully serious in this step. The solder joints must be carefully checked before molding.

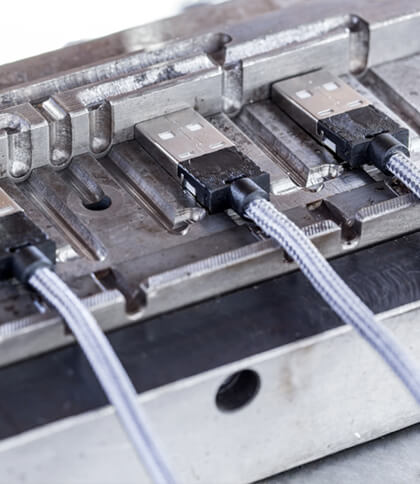

Operators energize the cable to ensure the formal operation and electronic parameter and filter out defective items. The cable quality standard that we follow is literally higher than the one of the original device cable. After passing the test, the external injection molding is applied to the connectors.

We lay stress on both of cables function and appearance. Operators will not miss checking every single detail of our cables. The cables with dents, scratches, cracks, deformation, contamination, shedding, corrosion and any other visual defects are filtered out or repaired.

The product tests must be comprehensively conducted before shipment, as we only sell quality-guaranteed cables to our clients.

The tests on electrical performance and data sync are functional basic. The wire bending and force inspections aim at ensuring the better durability. Additionally, other inspection will be performed based on product's special function.